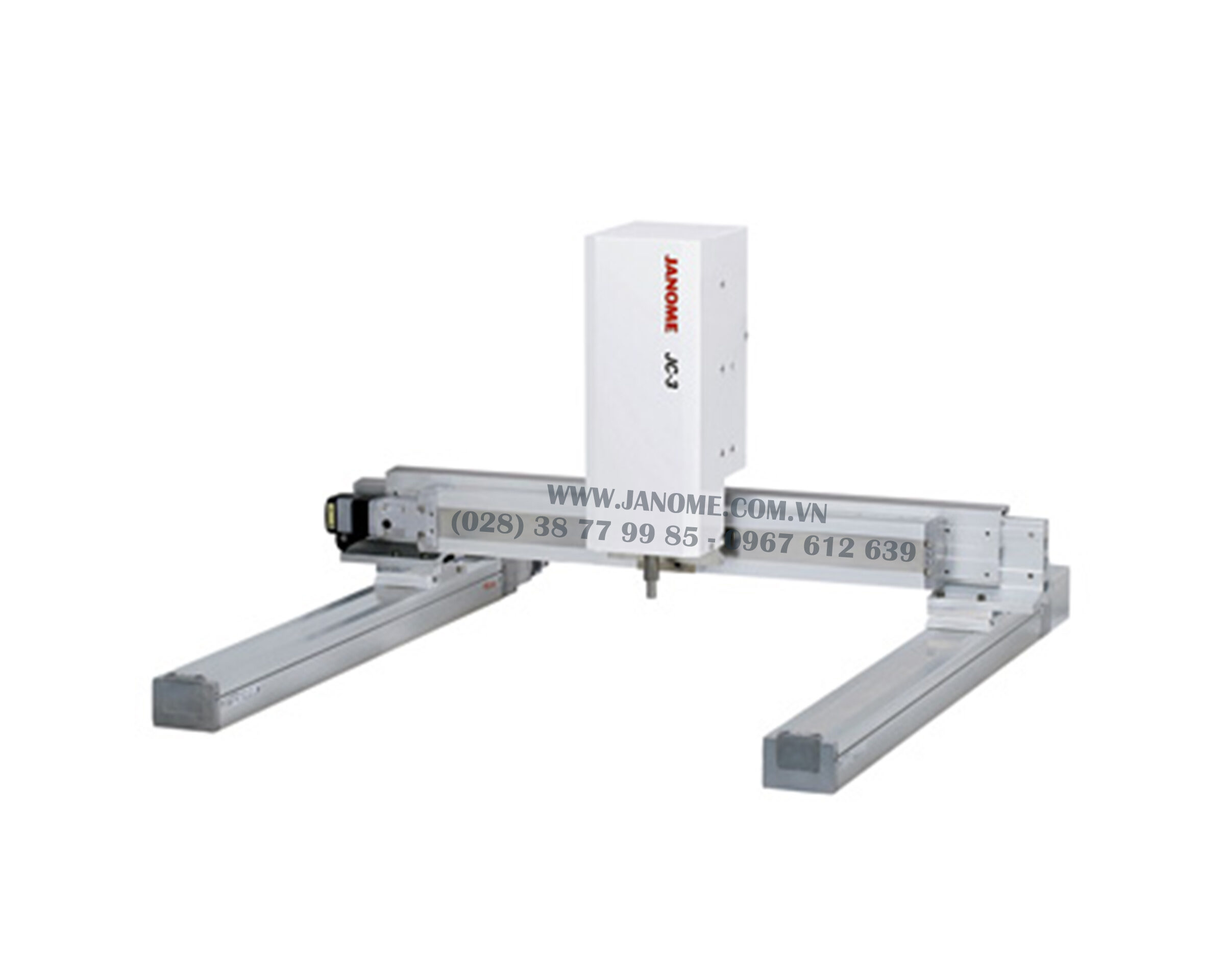

Easy Installation

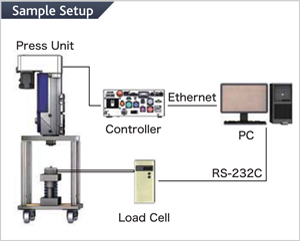

- Ethernet port included as standard equipment

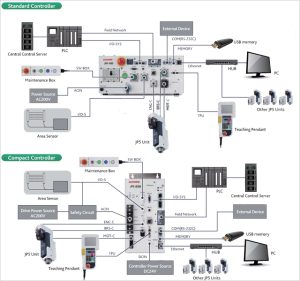

- Choose from 6 different Field Network types

- Low noise and clean work environment

- Much lower running cost compared with oil and air presses

- Easy program teaching

Faster ram movement for higher productivity

Max. ram speed up 2.5x; ram acceleration up 3.5x over our previous model.

Broad range of functions

A variety of pressing and sensor functions for high applicability many different fields.

Superior functionality contributes to higher production quality

- Load Precision: ±0.8% (FS)*1

- Repeatability: ±0.005mm*2

- *1 Value at 5% or more of maximum pressing capacity under constant environmental conditions.

- *2 Value with the press unit at a constant temperature.

Global Diagnostic Functionality

Comprehensive hardware diagnostics (including PC boards)

Its easy to switch among display languages; teach in one language and edit or run your program in another!

Auto Amp Adjustment ・Auto Load Calibration

Perform periodic load calibration automatically.*3

Optional Fully-Closed Model

Linear scale makes even more precise work possible.

*For more information, please visit our Catalog and Diagram Download or contact us directly.

Touch Panel Interface For Servo Press

View and analyze process parameters and graphs; comprehensive press control at your fingertips.

System Configuration Diagram

PC Software: TaS Ⅱ System

Compatible with desktop, laptop and HMI (touch panel) PCs; choose the PC setup suitable for your facility.

JP5 Designer

Create, edit, send and receive teaching data

- Upload teaching data from the Electro Press to your PC.

- Create and edit teaching data and send it to the Electro Press.

- Save teaching data on your PC and print it out.

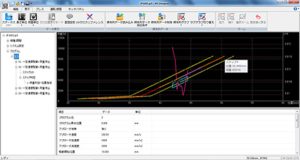

- Acquire time series data via JP5 Sampler and display it as a graph.

- Edit sensor conditions, etc. based upon graphic displays.

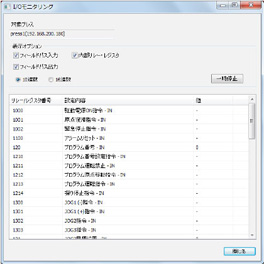

- Real time I/O monitoring during press operation.

JP5 Sampler (optional)

Receive and save run result data

- Upload run result data to your PC (minimum sampling interval 0.25msec).

- Display quality control data in list display format, and time series data as a graph.

- Output sampling data in CSV/TXT file format.

- Collect run result data from multiple presses.

JP5 Reporter (optional)

Analyze run results and make reports

- Use quality control data to calculate and display statistical averages and standard deviations.

- Display the frequency distribution (histograms) for end load values and end positions.

- Display CPK (process capability index) data based upon run result data.

- Display operational status program by program.

(Error rate, no. of OK/NOK, average cycle time, average prep time, etc.) - Make reports in HTML format.

nguồn: www.janomeie.com

Đánh giá

Chưa có đánh giá nào.